Explore Categories

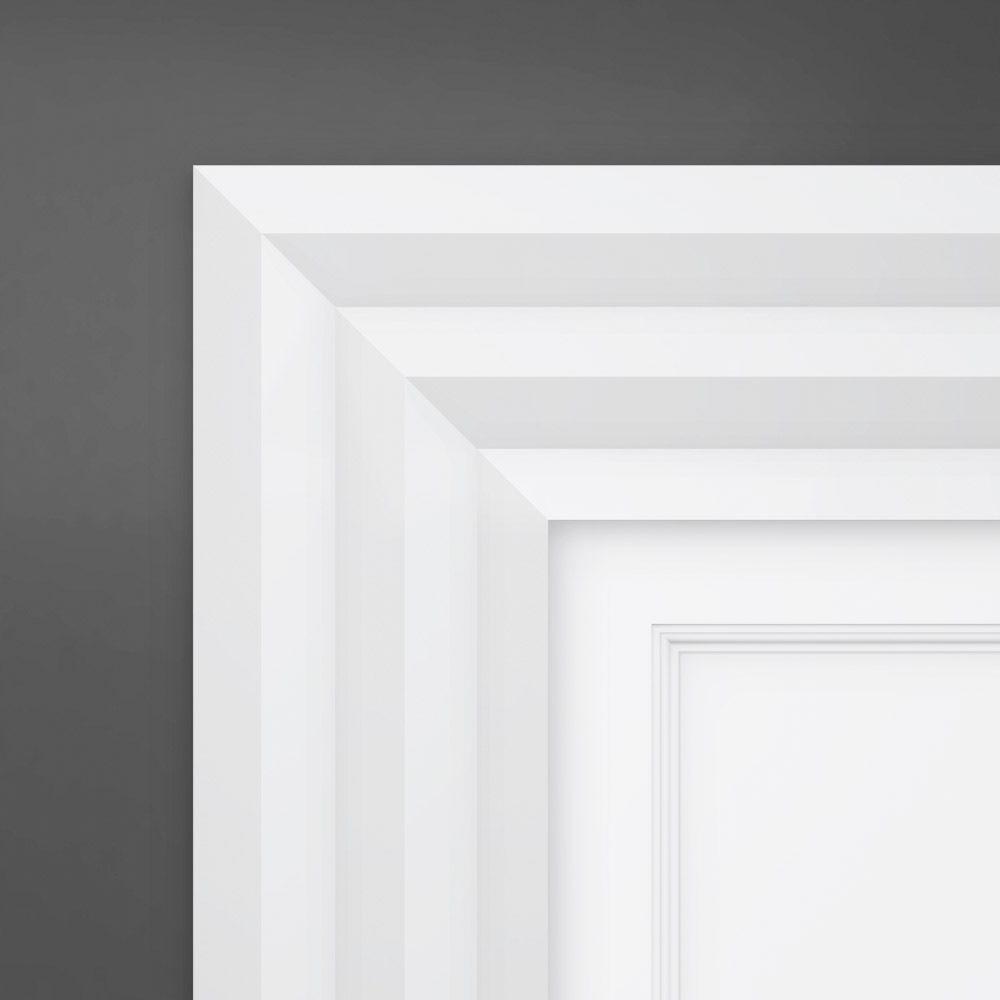

Casing

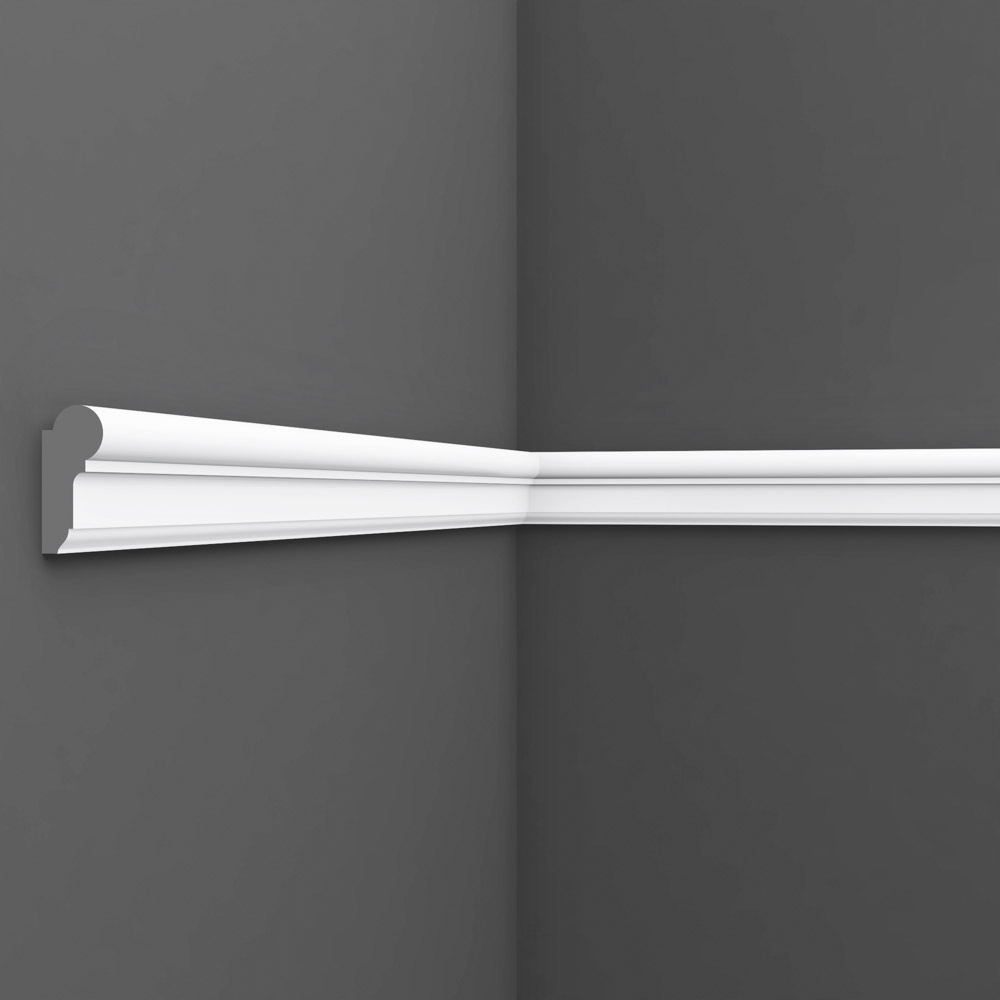

Backband

Baseboard

Crown

Chair Rail

Astragal

Bar Rail

Door Stop

Fillet

Handrail

Nosing

Plinth Block

Round

S4S

Shoe

Shoerail

Small Mouldings

Window Sill

Find the perfect match for any project with wood mouldings organized into trim packages tailored to any needs. Make installation at the next jobsite easy by browsing these categories, comparing proportions, and choosing the right wood moulding profiles to suit openings, ceilings, and wall details of all kinds. This hub also covers common wood moldings used across residential and commercial finish packages.

How to choose the right moulding category for a trim package

The first step to choosing a trim package is finding the right category to match the project. Window and door casing delivers the width and edge detail to accentuate openings, which makes it a good starting point. Baseboard moulding establishes the wall-to-floor transition and sets the baseline for proportioning the rest of the trim package. You can then coordinate crown and panel details to match, with sizes that fit the specific ceiling height and overall room proportions.

Crown molding profiles improve ceiling transitions and can be selected based on the room’s proportions and the desired shadow line. Deeper wood mouldings work better in taller spaces, while lighter profiles suit smaller rooms. Carefully confirm how you want the crown to terminate at corners, cabinets, and other fixtures before finalizing.

Panel moulding lets you create frames, wainscots, or wall breaks without having to change the base profile. Pair the base profile with base cap moulding or flat stock for a complete assembly. For build-ups, fillers, and returns, S4S lumber is the go-to option to achieve excellent results in any build or renovation. For multi-piece details and common built-up combinations, review moulding assemblies before finalizing profiles and takeoffs.

The right molding can greatly improve the impact of a room by emphasizing visual hierarchy. Whether drawing attention to openings, ceiling lines, or wall planes, molding selection can enhance overall project aesthetics. Plan carefully to avoid undersized trim in tall spaces or heavy builds in more compact rooms.

Materials, finishing, and profile coordination

Both appearance and finishing expectations rely heavily on material choice. Paint-grade trim package mouldings can deliver uniform color and crisp contours. Stain-intent options offer grain character and consistent tone for long runs. Always confirm before ordering to ensure the species and grade are available for your entire trim package.

The choice of wood species is just as crucial. Options like poplar and maple offer smooth faces and achieve predictable coating results. Cherry, oak, walnut, and mahogany can achieve stunning color with their defined grain. In other applications, pine and cedar can suit specific styles more affordably.

Reviewing samples under project lighting conditions can help you find the proper sheen, tone, and proportion. Sealers, stains, and clear coats achieve different effects based on application thickness, opening the door to many styles for interior trim mouldings. When working with existing trim, it may be possible to match materials, but it is often difficult.

Coordinating all of these factors is best handled by starting with a complete inventory of required trim and planned finishes. With so many options for species, grade, and profile available, knowing what the project calls for is essential. Trim packages make it easy to ensure consistency, no matter the scope of the project. For submittals and shop coordination, CAD downloads can help verify profile geometry before ordering.

When custom matching is the right move

Renovations, additions, and preservation work often call for matching existing trim. With enough attention to detail, this may be possible. Comparing physical samples and detailed measurements can help match the style, while achieving the same coating appearance in custom moulding and millwork will require some additional trial and error.