Explore Categories

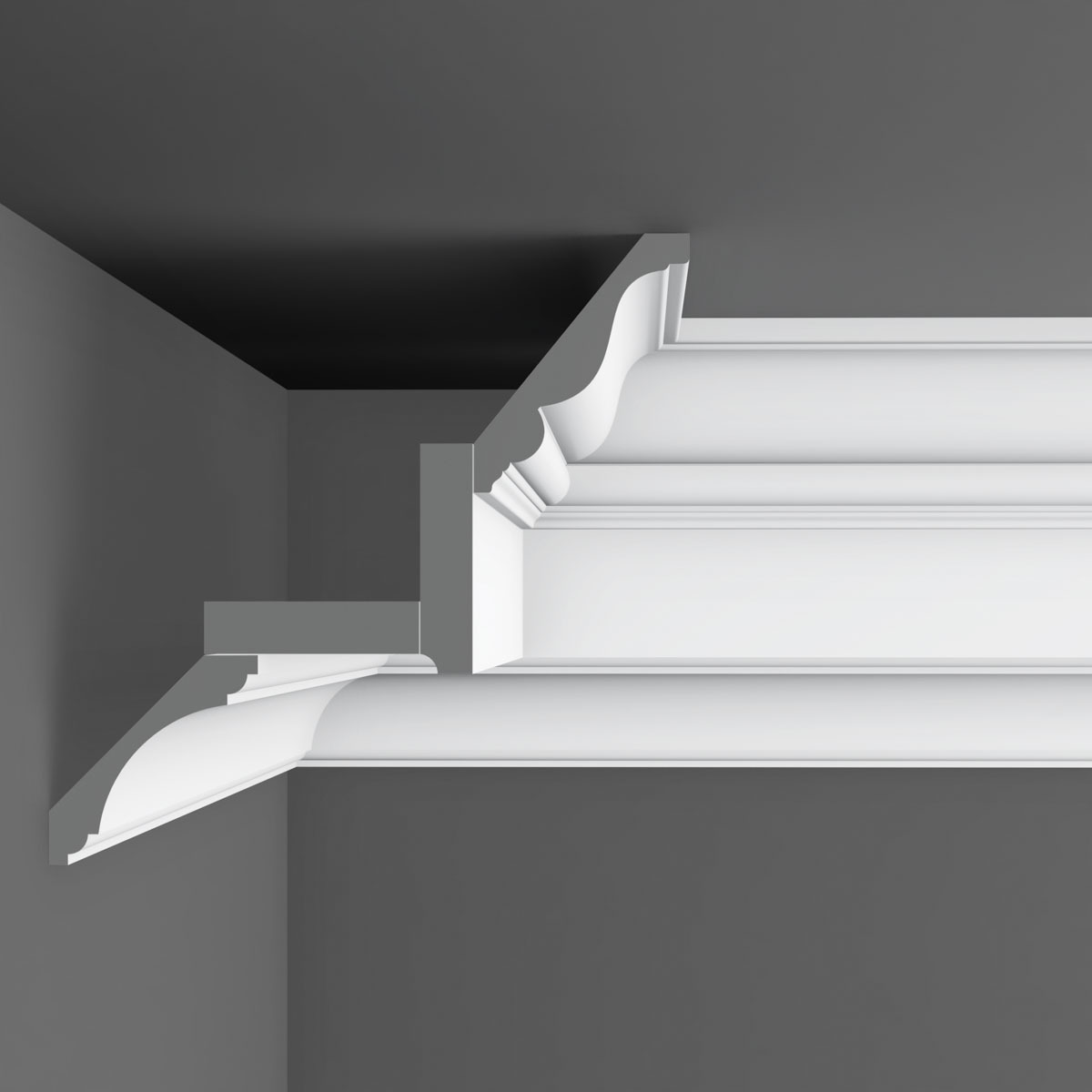

Moulding assemblies are thoughtfully composed groups of profiles—crowns, casings, baseboards, panel molds, and S4S elements—combined to create deeper, more architecturally expressive trim. These assemblies allow designers and builders to achieve custom, historically informed, or more substantial details without relying on a single oversized profile.

Mouldings One offers assemblies ranging from simple two-piece combinations to elaborate multi-profile entablatures. Each assembly is built from accurately milled components that follow classical proportions and traditional joinery principles drawn from historic examples.

Because assemblies rely on the language of mouldings—coves, cymas, fillets, astragals, and fascia elements—there is no single “correct” formula. Instead, homeowners, architects, and builders often design around the room’s existing trim style, ceiling height, or architectural period. Multi-piece crowns can add visual lift; layered casings deepen shadow lines; and built-up wainscot systems help create more formal, balanced rooms.

All assemblies can be painted or stained to match adjacent millwork. Using solid wood components provides durability and crisp detail, ensuring clean intersections and long-term stability. For exterior applications, proper sealing and maintenance are essential to preserve the integrity of the wood.

Explore our collection of common moulding assemblies—crowns, door and window headers, beams, wainscot systems, and multi-piece casings—or contact us for a quote. Mouldings One can also reproduce period-accurate assemblies for historic restoration work or assist in developing custom, project-specific designs.